Predictive maintenance for conveyors reduces unplanned downtime by using sensors and monitoring systems to detect problems before they cause complete equipment failure. These systems track vibration patterns, temperature changes, and belt wear in real time, allowing maintenance teams to fix issues during scheduled breaks instead of dealing with unexpected shutdowns that halt production.

Manufacturing facilities can lose an average of $260,000 per hour during unplanned downtime, according to industry research from Aberdeen Group. For operations running conveyor systems around the clock, a single belt failure or motor breakdown can cascade through the entire production line.

Predictive maintenance flips this scenario by shifting from reactive “fix it when it breaks” strategies to proactive monitoring that catches problems early.

The $1.2 Million Wake-Up Call

A certain plant manager’s (let’s call him David) phone rang at 2:47 AM on a Tuesday in March. The main conveyor line at his automotive parts facility was down, a bearing had seized and taken out the motor.

By morning, the team knew the full extent: the seized bearing destroyed the motor shaft, damaged the gearbox, and sent metal fragments into nearby components. Parts would cost $47,000. But that wasn’t the real problem.

Production stopped. The assembly line that needed those stamped parts sat empty. Workers waited. Customers called about delayed orders. David’s team tried to source replacement parts, but the motor wouldn’t arrive for three days.

The final damage, which included lost production, rush shipping to customers, overtime pay, and emergency repairs, came to $1.2 million. From one $200 bearing.

The worst part? The bearing had been failing for weeks. Maintenance heard the conveyor “sounding different,” but production quotas came first. Nobody knew that noise meant trouble.

Six months later, things work differently. Sensors track every bearing, motor, and belt. Last Thursday, the system caught unusual vibration in Conveyor Line 3. Maintenance checked it out during Saturday’s scheduled downtime and found a bearing starting to fail, the same thing that caused their March breakdown.

They swapped the $200 bearing in a four-hour window. Total cost: $850. Lost production: none.

That shift from fixing breakdowns to catching problems early is what predictive maintenance does.

Understanding Predictive Maintenance Technology

Modern conveyor monitoring combines sensors with intelligent software to create an early warning system for equipment failures, transforming maintenance from guesswork into data-driven decisions.

Types of Sensors and Their Functions

What types of sensors are used in predictive maintenance? Predictive maintenance uses four primary sensor types:

- Vibration sensors detect bearing and motor issues

- Temperature monitors spot overheating components

- Belt tracking sensors measure alignment problems

- Current sensors identify electrical issues in drive motors

These sensors work together to provide comprehensive equipment monitoring.

Vibration sensors detect unusual shaking in motors and bearings, temperature monitors spot overheating before components fail, and belt tracking sensors measure alignment to prevent costly damage. Current sensors identify electrical issues in drive motors before they lead to burnout. Each sensor type addresses specific failure modes common in conveyor operations.

How Software Platforms Analyze Data

The real power comes from connecting these sensors to software platforms that analyze the data. These systems establish baseline performance levels for your specific equipment, then flag deviations that signal developing problems. Some advanced platforms even use machine learning to predict when components will likely fail based on historical patterns.

Did You Know? According to the U.S. Department of Energy’s Federal Energy Management Program, implementing predictive maintenance can reduce breakdowns by 70-75% and lower maintenance costs by 25-30% compared to reactive maintenance approaches.

How Predictive Maintenance Prevents Downtime

Catching problems early transforms maintenance from emergency response to planned optimization, providing visibility into equipment health impossible with traditional approaches.

How Do Sensors Detect Problems Before Breakdowns Occur?

Sensors detect problems by continuously monitoring equipment performance and flagging abnormal patterns weeks before failure. Vibration sensors identify bearing wear patterns, temperature monitors spot gradual heat increases, and belt tracking systems detect millimeter-level drift—all while equipment still operates normally.

Vibration analysis provides one of the most valuable early warning signals. When bearings wear out, they create distinct vibration patterns long before they seize. A vibration sensor might detect these patterns weeks in advance, giving your team time to order parts and schedule repairs during planned maintenance windows.

Temperature monitoring works similarly. Motors and bearings generate more heat as they wear down or when lubrication breaks down. A motor running 15 degrees hotter than normal might seem fine, but that heat signature tells maintenance staff that internal components are under stress.

Belt tracking sensors prevent expensive failures. When belts drift off center, they create uneven wear and system stress. Modern sensors detect millimeter-level drift and alert operators immediately, preventing belt tears, frame damage, and product loss.

Real-World Manufacturing Impact

Dorner’s conveyor systems can be configured with monitoring capabilities that help facilities avoid costly disruptions.

Consider an automotive parts manufacturer running conveyors 20 hours daily. Before predictive maintenance, they experienced eight unplanned stoppages monthly, each lasting 2-4 hours. After adding sensors, unplanned stops dropped to fewer than two per month, with most issues caught during scheduled maintenance.

The financial impact extends beyond avoiding downtime. When you catch a bearing starting to fail, you replace one bearing. Wait until catastrophic failure, and you might replace the bearing, motor shaft, and repair surrounding component damage.

Comparing Maintenance Approaches

Understanding how predictive maintenance differs from other strategies helps clarify its value and return on investment.

Reactive vs. Predictive

Predictive maintenance monitors actual equipment condition and bases maintenance decisions on real-time data rather than assumptions. This optimizes both uptime and maintenance spending by addressing problems at the ideal moment.

Reactive maintenance means fixing things only when they break, which requires minimal upfront investment but leads to maximum downtime and often results in more expensive repairs.

| Maintenance Type | Downtime | Cost | Efficiency |

| Reactive | Highest | High (emergency repairs) | Lowest |

| Predictive | Lowest | Lowest (optimal timing) | Highest |

Multiple analyses and DOE-cited summaries report that predictive maintenance can reduce maintenance costs by roughly 25–30% compared to traditional or purely reactive approaches

Measuring Success and ROI

Proving the value of predictive maintenance requires tracking specific metrics before and after implementation. Key performance indicators include mean time between failures (MTBF), which should increase by 30-50% or more with effective predictive maintenance. Mean time to repair (MTTR) typically drops by 20-40% because the predictive system provides advance notice for part ordering and repair planning.

Maintenance cost per operating hour usually decreases by 15-30%, while unplanned downtime incidents can be reduced by 70% or more. For example, a Forbes Tech Council article notes “the average manufacturer confronts 800 hours of equipment downtime per year”. At $260,000 per hour, that’s over $200 million in lost productivity. Even modest improvements in uptime through predictive maintenance deliver substantial returns.

Implementation Guide for Your Facility

Starting a predictive maintenance program doesn’t require a massive investment. Here’s how to approach it strategically for maximum impact.

Starting with Logistics Operations

Warehouse and distribution operations face unique challenges with multiple shift patterns, varying product loads, and complex sortation systems where any breakdown creates immediate bottlenecks.

Dorner’s FlexMove conveyor systems, as an example, can integrate monitoring technology that addresses these challenges. Logistics operations benefit particularly from belt condition monitoring since distribution centers push high volumes through conveyors, causing faster belt wear.

Motor current analysis proves valuable in sortation systems with multiple divert points. Current signatures reveal when motors struggle or draw excessive power, indicating mechanical binding, worn components, or electrical issues.

Pro Tip: Start with your most critical conveyor lines when implementing predictive maintenance. These high-impact areas deliver the fastest ROI and help your team build expertise before expanding.

Overcoming Common Challenges

Implementation isn’t without hurdles. Here are the most common obstacles and practical solutions.

Initial Costs: Sensor and software expenses can seem high, especially when capital budgets are tight. Focus on demonstrating quick wins with a small pilot program. Many organizations find that preventing just one or two major breakdowns pays for their initial investment.

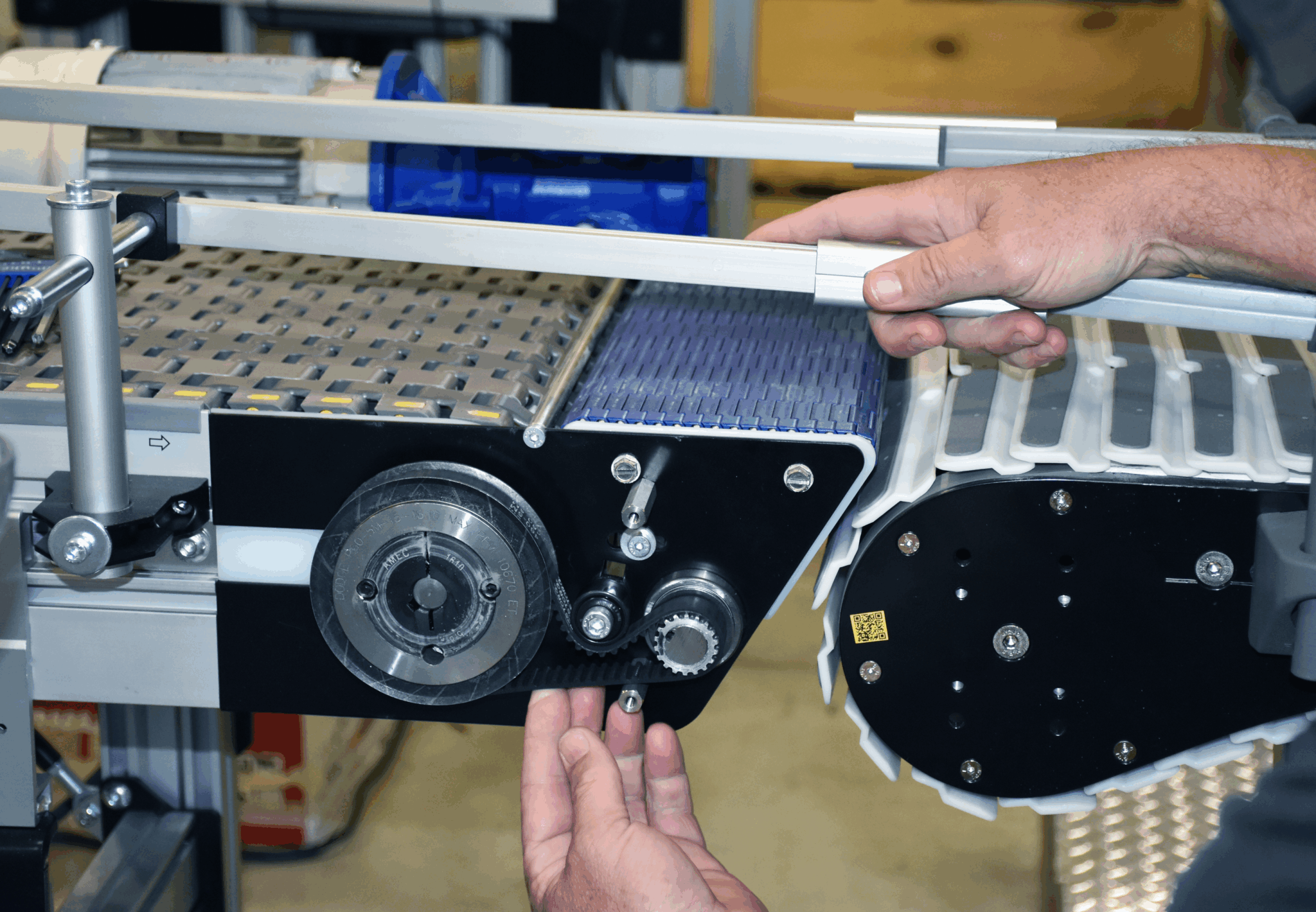

Integration with Older Systems: Modern retrofit sensors can be added to almost any conveyor equipment. Wireless sensors eliminate the need for complex wiring in existing systems. Work with conveyor specialists like Dorner who understand both legacy equipment and modern monitoring technology.

Team Resistance: Maintenance teams sometimes resist changing established routines. Involve staff in planning from the start and emphasize that predictive maintenance makes their jobs easier by eliminating emergency repair pressure. Training is essential to build confidence with new tools.

Alert Fatigue: Systems generating too many notifications can be addressed by fine-tuning alert thresholds after establishing baselines. Modern systems let you adjust sensitivity so alerts indicate genuine issues rather than minor fluctuations.

Getting Started with Predictive Maintenance

Begin by identifying your most critical conveyor lines and the types of failures they’ve experienced. A conveyor that fails due to bearing problems is an excellent candidate for vibration monitoring, while one with recurring belt issues needs tracking and wear detection. Connect with conveyor system experts like Dorner, who can recommend appropriate sensor technology for your specific equipment or processes, and help you establish baseline performance metrics.

The facilities seeing the greatest success treat predictive maintenance as an ongoing program that evolves with their needs, not a one-time project. Document current downtime incidents, maintenance costs, and failure patterns to measure ROI and justify program expansion.

Ready to reduce unplanned downtime? Contact Dorner’s parts and services team to discuss predictive maintenance solutions for your operation.

Frequently Asked Questions

How much does predictive maintenance cost?

Initial investment typically ranges from $5,000-$25,000 per conveyor line, depending on system complexity and sensor types. Most facilities see ROI within 12-18 months through reduced downtime and lower repair costs.

Can predictive maintenance be added to existing conveyors?

Yes, modern retrofit sensors can be added to almost any conveyor equipment. Wireless sensors eliminate complex wiring needs, making installation straightforward even on older systems.

In new systems, sensors can be easily integrated during the conveyor assembly, reducing future upgrade costs. Dorner’s engineering experts can help you decide which sensors and monitoring equipment make the most sense for your specific equipment and needs.

What sensors are needed for predictive maintenance?

Most systems use vibration sensors for motors and bearings, temperature monitors for overheating detection, and belt tracking sensors for alignment. The specific sensor package depends on your equipment and failure history.

How long does it take to see ROI from predictive maintenance?

Typical ROI timelines range from 12-18 months, though facilities often see immediate benefits from preventing their first major breakdown. The ROI accelerates as your team gains experience with the system.

Do I need special software to manage predictive maintenance data?

Most modern sensor systems include cloud-based software platforms for data analysis and alerts. These platforms establish performance baselines and flag issues automatically, requiring minimal technical expertise to operate.